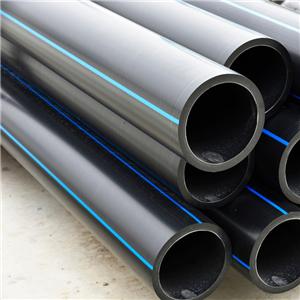

HDPE pipe supplier

-

Hot

Potable HDPE Pipe HDPE Tube Manufacturer

HDPE pipe comprehensive performance channel application field | temperature resistance | low temperature embrittlement temperature is very low, can be used in the range of - 40 to 60 C, winter installation construction will not occur pipeline embrittlement. Jingtong HDPE Pipe has received the ISO9001:2008 Quality Management System certification, ISO14001:2004 Environmental Management System certification, and OHSAS18001:2007 Occupational Health and Safety Management System certification. In 2020 year, Jiongtong hdpe pipes and fittings got the CE certificate.

Email Details -

Hot

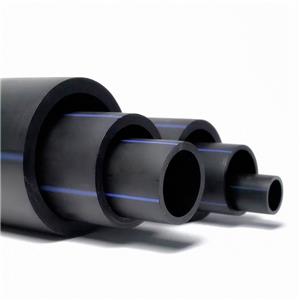

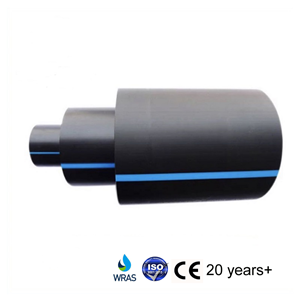

PE80 PE100 Pipe PE Tube

HDPE pipes will be melted between 190 n 240 C. Using this characteristic, the two melted parts of the pipe (or fittings) will be fully contacted and maintained at appropriate pressure. After cooling, the two parts can be firmly integrated. Therefore, the connection mode of PE pipe is different from that of U-PVC pipe. Usually, HDPE Pipe adopts two ways: electro-thermal fusion connection and hot-melt butt connection. According to the size of pipe, it can be divided into: injection hot-melt socket connection when DN is less than 63; hot-melt butt connection or electric-melt socket connection when DN is more than 75; flange or wire connection when connecting with different materials. The diameter of HDPE pipeline ranges from DN16 to DN2500, which is divided into 36 levels. Pressure levels ranged from 0.4 Mpa to 2.5 Mpa, with a total of eight grades.

Email Details -

Hdpe Silicon Core Pipe for optical fiber cable

The HDPE silicon core tube is a new type of composite pipe with a silicone solid lubricant on the inner wall. It has good sealing performance, chemical corrosion resistance and low engineering cost. It is widely used in optical fibre cable communication network systems for highways and railways. Synchronous extrusion compounding is carried out by three plastic extruders. The main raw material is high-density polyethylene, and the core layer is a solid lubricant silica gel with the lowest friction coefficient. Widely used in optical cable communication network systems.

Good Price HDPE silicon pipes Silicon Hdpe Pipe supplier China Hdpe Silicon Core Pipe Optical Fiber PE conduit pipeEmail Details